The EN 388 Standard Explained

As a Safety Officer, your primary mission is to protect your team. Hand injuries are one of the most common and costly workplace incidents, and the first line of defense is a reliable pair of gloves. You rely on the EN 388 Standard Explained to make informed purchasing decisions, but what if the very standard you trust is being mistaken or intentionally hidden by your Glove Supplier/Manufacturer?

What is the EN 388 Standard?

The EN 388 standard is the European benchmark for assessing a glove’s protection against mechanical risks, including abrasion, cut, tear, and puncture. However, the 2016 revision introduced big changes that many manufacturers and suppliers have been slow to adopt. This guide covers the seven secrets about the EN 388 standard. By understanding these nuances, you can ensure your team is equipped with genuinely compliant and effective Personal Protective Equipment (PPE). After reading this blog, you’ll be an industry expert from a normal B2B buyer, and able to save your company’s bottom line from heavy fines or penalties.

Your Current EN 388 Gloves Might Be Outdated!

If your current stock of EN 388 Gloves still displays the old four-digit rating (e.g., 4544) without the new letter and optional ‘P’ designation, you are likely using Outdated PPE. The 2016 revision of the standard (EN 388:2016) was a big shift to more accurate testing of modern, high-performance materials.

The old standard failed to account for advanced materials like fiberglass and basalt, which rapidly dull the testing blade. It leads to misleading cut resistance scores. The secret is that any glove tested only under the old protocol may not offer the protection level you think it does, which puts the workers at unnecessary risk.

Secret #1: The TDM Cut Test is the Only Cut Rating That Matters

The TDM Cut Test is the definitive measure for modern, high-performance cut-resistant gloves. This is the secret your manufacturer or supplier may not highlight because it shows the limitations of older, cheaper products.

The TDM-100 test (ISO 13997) measures the force (in Newtons) required to cut through a sample glove material using a straight, fresh blade in a single, controlled motion. This test is far more accurate and reliable for today’s advanced materials. The result is represented by a letter, A through F, as the fifth character in the EN 388 rating, with ‘F’ being the highest level of protection.

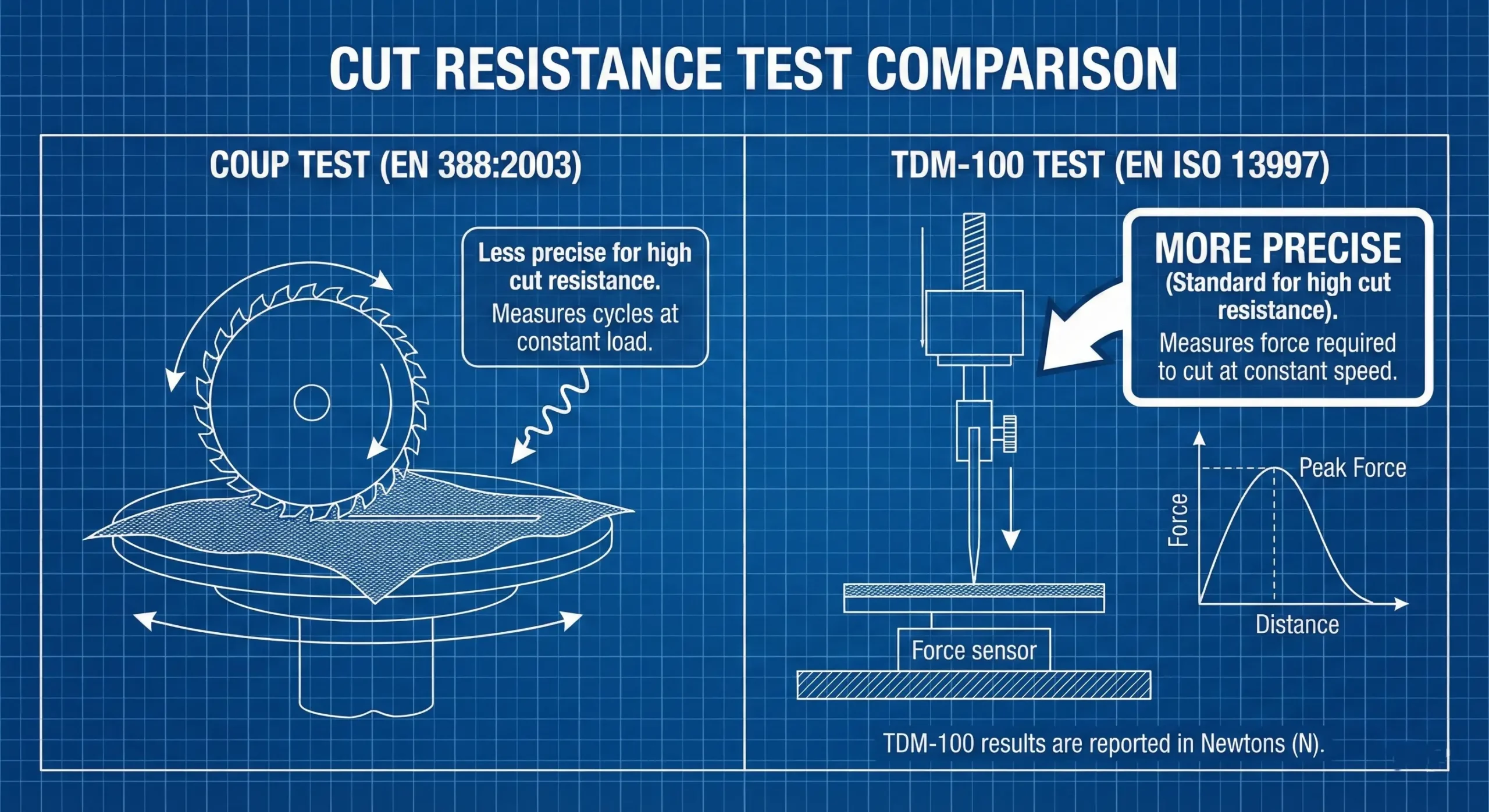

TDM vs. Coup:

The traditional Coup Test, represented by the second digit (1-5), uses a rotating circular blade that moves back and forth under a fixed load. The problem is that the blade dulls quickly when testing materials with high cut resistance, like those containing glass or steel fibers. A dull blade requires more cycles to cut through the material, artificially inflating the score.

The EN 388:2016 standard mandates that if the Coup Test blade dulls, the test must be stopped, and the TDM-100 test must be performed instead. If a glove is highly cut-resistant, its rating will show an ‘X’ in the second position (Coup Test) and a letter (A-F) in the fifth position (TDM Cut Test), confirming it was tested with the superior method.

For example, a certified gloves manufacturer, Candino Group of Industries, offers a Goatskin Cut-Resistant Glove rated 2X22E, where the ‘X’ and the ‘E’ clearly indicate testing with the TDM method to achieve a Level E cut resistance.

| Test Method | EN 388 Position | Rating Scale | What It Measures |

|---|---|---|---|

| Coup Test | 2nd Digit | 1 to 5 | Cycles to cut through material (can be inaccurate) |

| TDM-100 Test | 5th Letter | A to F | Force (Newtons) required to cut through material (accurate) |

Interesting Fact: A glove with a Coup Test rating of ‘5’ may only achieve a TDM rating of ‘C’ or ‘D’. Always look for the letter rating (A-F) to determine the true Cut Rating of a high-performance glove.

Secret #2: The Hidden ‘P’ Rating (Impact Protection)

Hand injuries are not just cuts and abrasions; they are also crushing and pinching injuries. The secret here is the optional, but vital, sixth character in the EN 388 rating: the EN 388 Impact Rating.

If a glove has been tested for Impact Protection according to the EN 13594:2015 standard and passes, the letter ‘P’ will appear as the sixth and final character. If the glove is tested and fails, or if it is not tested at all, a dash (-) or an ‘X’ will appear. A ‘P’ signifies that the glove has protective padding designed to absorb impact energy to the knuckles and/or back of the hand, significantly reducing the risk of crushing injuries.

For instance, Candino Group of Industries’ Goatskin Cut-Resistant Glove line includes models rated 2X22EP, demonstrating a commitment to both high cut protection (Level E) and essential impact resistance (‘P’).

Which Industries Must Demand the EN 388 Impact Rating?

While all industries benefit from added protection, certain sectors face a high risk of impact injuries and should make the EN 388 Impact Rating a mandatory requirement for their PPE procurement. This is a non-negotiable aspect of modern Industrial Safety.

| Industry | Primary Impact Hazard | Why ‘P’ is Essential |

|---|---|---|

Oil & Gas | Dropped tools, swinging equipment, pinch points | High-energy impacts are common in drilling and rigging operations. |

Construction | Falling debris, hammer strikes, heavy machinery operation | Protection against blunt force trauma to the back of the hand. |

Mining | Rock falls, heavy equipment maintenance, confined spaces | Crushing hazards from machinery and moving materials. |

Automotive/Heavy Maintenance | Wrenches slipping, components falling, engine work | Protection for mechanics and assembly line workers. |

Secret #3: Abrasion Resistance is Not the Same as Durability

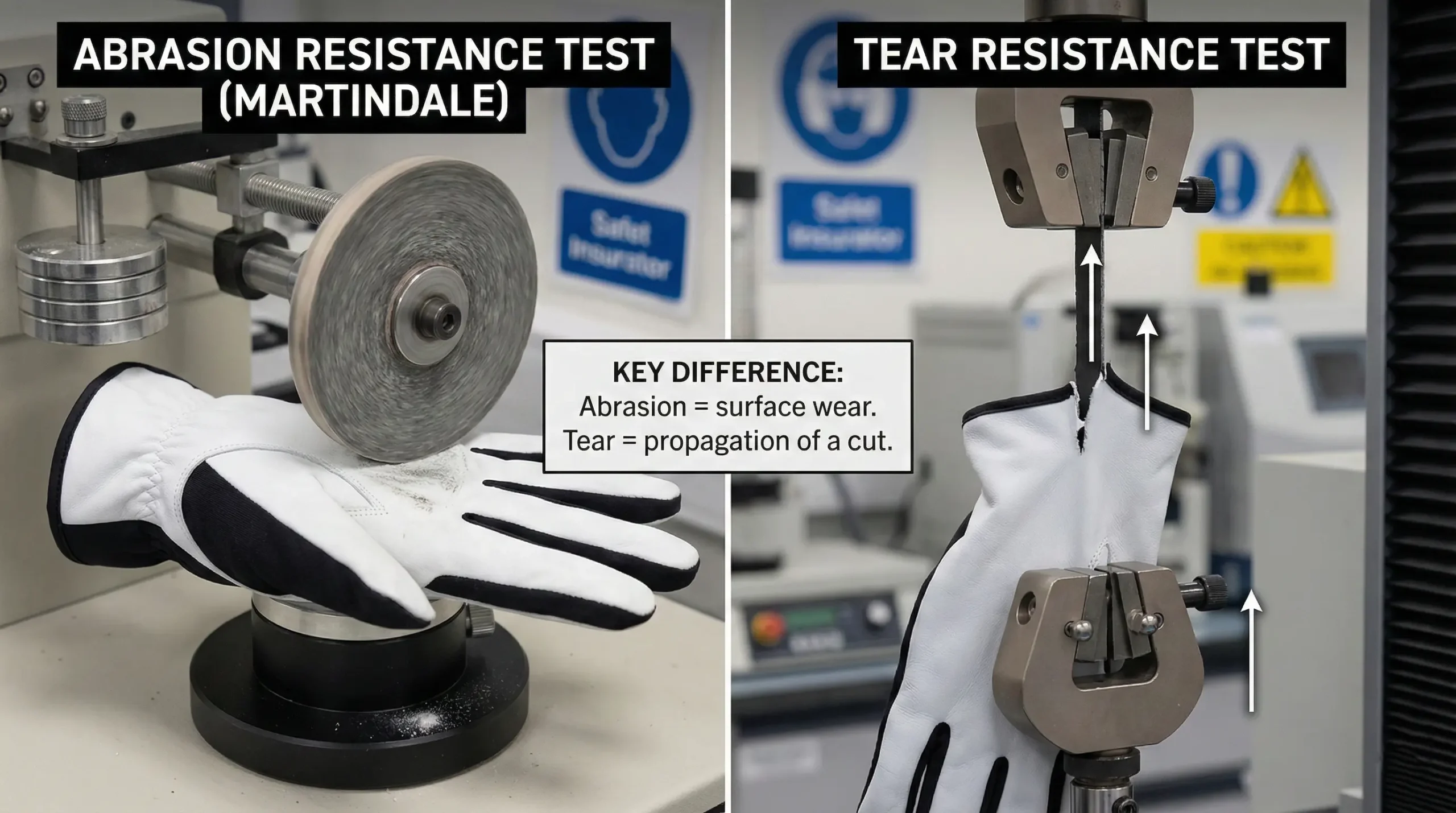

Your supplier might claim a high Abrasion Resistance score, but this is only part of the story of Glove Durability. The secret is that a glove can have excellent abrasion resistance but tear easily, making it useless after a single snag.

Abrasion resistance, the first digit in the EN 388 rating (1-4), measures how well the glove material resists wear when rubbed against a rough surface. The test uses a Martindale abrasion machine, which rubs a sample of the glove material with sandpaper under a specific pressure. The score is based on the number of cycles required to rub a hole through the material.

What Does Your Abrasion Score Really Mean?

The Abrasion Score is a crucial indicator of a glove’s lifespan in environments with constant friction, but it must be considered alongside the tear resistance (the third digit). A high abrasion score (Level 4) means the glove will last longer when handling rough materials like concrete, bricks, or coarse metal.

| Abrasion Score (1st Digit) | Minimum Cycles Required | Interpretation |

|---|---|---|

1 | 100 cycles | Minimal resistance, suitable for light-duty tasks. |

2 | 500 cycles | Moderate resistance, general handling. |

3 | 2,000 cycles | Good resistance, suitable for medium-duty work. |

4 | 8,000 cycles | Excellent resistance, maximum lifespan in abrasive environments. |

Key Takeaway: When reviewing the EN 388 Digits, look for a balanced score. A glove with a rating of 4X43F is superior in durability (Abrasion 4, Tear 4) to a glove rated 4X13F (Abrasion 4, Tear 1), even though both have the same cut resistance.

For example, a well-balanced glove, Candino Group of Industries’ Goatskin Assembly Glove rated 2122X, provides a Level 2 Abrasion score, indicating a reliable lifespan for general handling tasks.

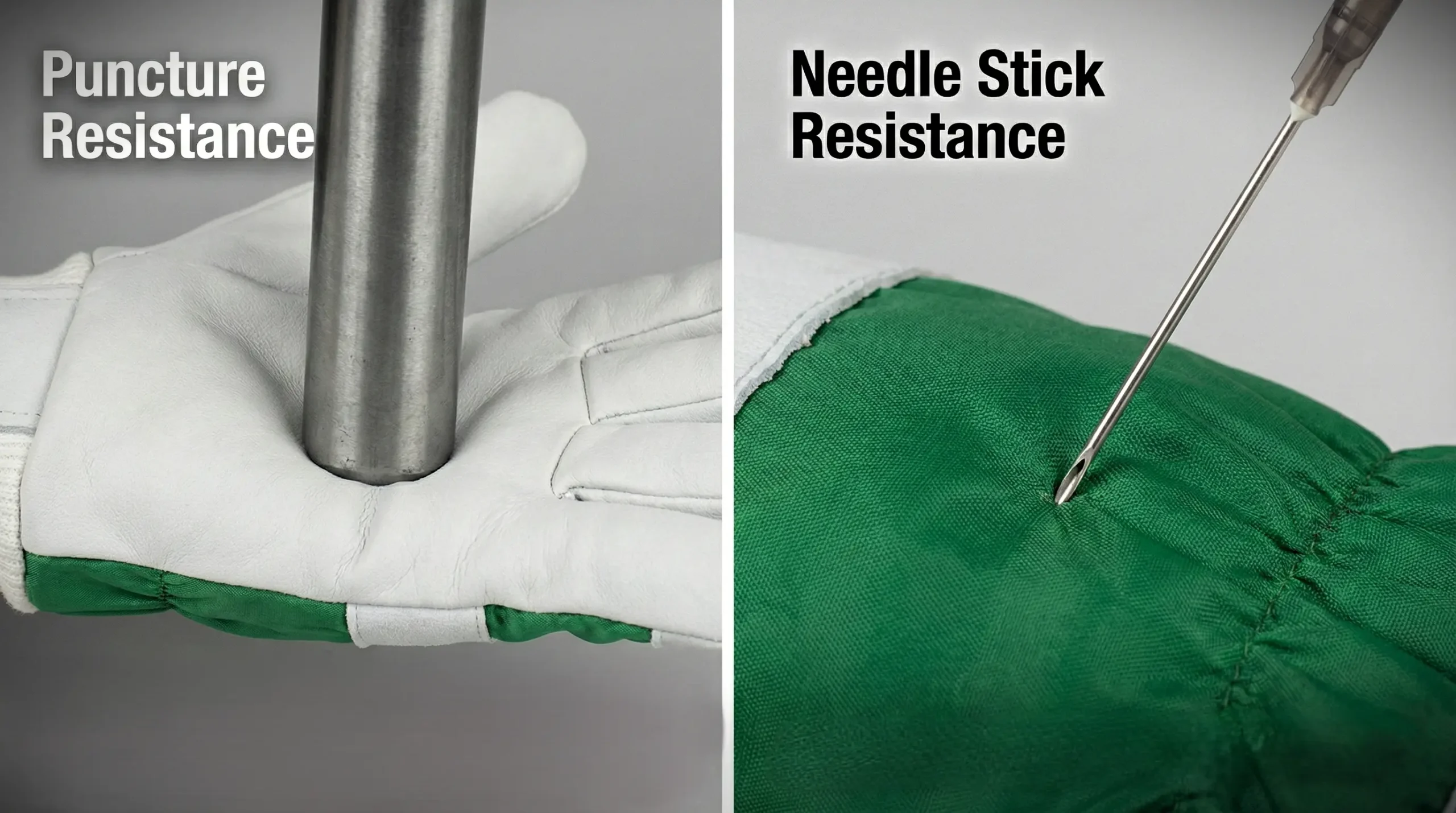

Secret #4: How Manufacturers “Game” the Puncture Resistance Score

The Puncture Resistance rating (the fourth digit, 1-4) is perhaps the most misunderstood and easily “gamed” score. The secret is that the EN 388 puncture test is designed to measure resistance against blunt objects, not sharp needles or hypodermics.

The test uses a standardized, blunt-tipped steel probe (1mm in diameter) to measure the force required to push through the glove material. Manufacturers can achieve a high score (Level 4) by simply using thicker, denser materials, which may compromise dexterity and comfort, the very factors that lead to non-compliance on the shop floor.

For example, a general-purpose glove like Candino Group Of Industries’ Cowhide Canadian Glove is rated 2142X, offering a Level 2 Puncture score, adequate for many industrial tasks, but not a substitute for specialized needle stick protection.

Difference Between Puncture and Needle Stick Protection

This is the most important distinction for any Safety Officer: Puncture Protection is not the same as Needle Stick Protection.

- Puncture Resistance (EN 388): Protects against large, blunt objects like nails, splinters, or metal fragments.

- Needle Stick Protection (Specialized Testing): Protects against fine, sharp objects like hypodermic needles, wires, or bone fragments. This requires specialized materials and is often tested under a separate standard (e.g., ASTM F2878).

If your workers are exposed to hypodermic needles or fine wires, relying solely on a high EN 388 puncture score is a dangerous mistake. You must demand gloves that are specifically tested and rated for Needle Stick Protection.

Secret #5: Why You Need a Transparent Supply Chain for EN 388 Compliance

In the wake of global supply chain disruptions, the secret to guaranteed compliance is demanding a Transparent Supply Chain from your Glove Supplier. A non-transparent supply chain is a breeding ground for counterfeit or substandard PPE, which may carry fraudulent EN 388 markings.

A truly compliant manufacturer will provide complete documentation, including:

- Declaration of Conformity (DoC): A legal document stating the product meets the requirements of the relevant EU regulation (e.g., PPE Regulation (EU) 2016/425).

- Technical File: Detailed information on the design, manufacturing, and testing of the glove.

- Notified Body Certificate: Proof that the product has been tested and certified by an accredited third-party laboratory (Notified Body).

The Manufacturer’s Role in Testing and Certification

The manufacturer’s commitment to EN 388 Compliance is demonstrated through rigorous Glove Testing and PPE Certification. They should be able to trace every batch of gloves back to the raw materials and the specific testing reports. If your supplier cannot immediately provide the Notified Body certificate for the EN 388 rating, it is a massive red flag.

Actionable Tip: Ask your supplier/manufacturer for the name and number of the Notified Body that certified the glove. You can then independently verify the certificate on the Notified Body’s public register.

Why Choose Candino Group Of Industries?

When the safety of your team and the integrity of your compliance program are on the line, you need a partner whose commitment to the EN 388 standard is absolute. Candino Group Of Industries shows this commitment through accurate testing and transparent reporting that ensures every glove delivers the exact-mentioned protection level. We don’t just sell gloves; we provide certified hand protection.

Here is the data of our core product line’s EN 388:2016 performance ratings, presenting our dedication to balanced protection across various materials:

| Material | Glove Type | EN 388:2016 Rating | Key Protection Highlight |

|---|---|---|---|

| Goatskin | Assembly Gloves | 2122X | Excellent dexterity with good tear and puncture resistance. |

| Goatskin | Driving Gloves | 2122X | Balanced mechanical protection for general handling. |

| Goatskin | Canadian Gloves | 2122X | Reliable all-purpose protection. |

| Goatskin | Welding Gloves | 2122X | Good tear resistance for demanding tasks. |

| Goatskin | Winter Gloves | 2122X | Protection is maintained in cold conditions. |

| Goatskin | Cut-Resistant Gloves | 2422C, 2X22E, 2422CP, 2X22EP | High cut resistance (Level C or E) with optional impact protection (‘P’). |

| Sheepskin | Assembly Gloves | 1121X | High dexterity for fine motor tasks. |

| Sheepskin | Welding Gloves | 2142X | High tear resistance (Level 4) for durability. |

| Sheepskin | Winter Gloves | 2142X | High tear resistance (Level 4) for durability in cold. |

| Sheepskin | Cut-Resistant Gloves | 2422C | Solid cut resistance (Level C) with good tear resistance. |

| Cowhide | Canadian Gloves | 2142X | Excellent durability with high tear resistance (Level 4). |

Partner with an EN 388 Expert

You now possess the five secrets that differentiate an informed Safety Officer from a typical buyer. You understand that the EN 388 Standard Explained is more than just four digits; it’s a complex, six-character code that dictates the true level of protection.

Stop relying on vague claims and start demanding transparency and compliance. Partner with a safety expert who understands the nuances of TDM vs. Coup, the necessity of the ‘P’ impact rating, and the financial power of the Cost-Per-Use formula. Your role is to protect your team, and the right Safety Partner will help you do it with confidence and fiscal responsibility.

Download Your Free EN 388 Compliance Checklist

Ensure every glove you purchase meets the highest standards. Click here to Download Your Free EN 388 Compliance Checklist.

Frequently Asked Questions (FAQs)

Q1: What is the main difference between the old EN 388 (2003) and the new EN 388:2016 standard?

The main difference is the introduction of the TDM-100 cut test (represented by the fifth character, a letter A-F) for high-performance materials. The old Coup Test was found to be unreliable for modern, high-cut-resistant materials because the blade would dull quickly, leading to artificially high scores. The 2016 standard also added the optional ‘P’ rating for impact protection as the sixth character.

Q2: How do I read the full EN 388:2016 pictogram rating?

The rating consists of four numbers and two letters (e.g., 4 X 4 3 F P).

- Abrasion Resistance (1-4)

- Coup Cut Resistance (1-5, ‘X’ if TDM test was used)

- Tear Resistance (1-4)

- Puncture Resistance (1-4)

- TDM Cut Resistance (A-F, ‘X’ if not tested)

- Impact Protection (P for Pass, F for Fail, X for Not Tested)

Q3: Is the EN 388 standard the same as the ANSI/ISEA 105 standard used in the US?

No, they are different standards, though they share the same goal of protecting hands from mechanical risks. ANSI/ISEA 105 is the US standard, while EN 388 is the European standard. The key difference is in the cut resistance rating scale: EN 388 uses a letter scale (A-F) for the TDM test, while ANSI/ISEA 105 uses a numeric scale (A1-A9). Both standards use the same TDM-100 test method for cut resistance, making the results comparable, but the rating scales are distinct.

Q4: If a glove has a high Puncture Resistance (Level 4), is it safe against hypodermic needles?

Absolutely not. This is a critical misconception. The EN 388 puncture test uses a large, blunt probe (1mm diameter) to test resistance against objects like nails or splinters. Protection against fine, sharp objects like hypodermic needles (Needle Stick Protection) requires specialized materials and is tested under a separate standard (e.g., ASTM F2878). Always look for a specific needle stick rating if that is the hazard.

Q5: What does the ‘X’ mean in an EN 388 rating?

The ‘X’ is a placeholder that means the test was either not performed or the test is not applicable to the glove. For example, if you see ‘X’ in the second position (Coup Test), it means the Coup Test was not performed because the TDM-100 test (fifth position) was used instead, which is the preferred method for high-performance cut-resistant gloves.